What is the common factors of bubbles and scratches in glass bottle production, here are 8 Common Causes we are going to talk about it.

1. When the glass material blank falls into the initial mold, it cannot accurately entered, and the friction with the mold wall is too large to form creases.

2. The scissors marks of the feeder are too large, and the scissors scars appear on the bottle body after individual glass bottles are formed.

3. The initial mold and molding material of the glass bottle are poor, the density is not enough, and the oxidation is too fast after high temperature, forming small pits on the surface of the mold, resulting in an unsmooth surface of the glass bottle after molding.

4. The poor quality of glass bottle mold oil will make the mold not lubricated enough, the dripping speed will be reduced, and the material type will change too quickly.

5. The design of the initial mold is unreasonable, the mold cavity is too large or too small, and after the gob enters the molding mold, it is blown up and spreads unevenly, which will cause spots on the glass bottle.

6. The machine dripping speed is not uniform, and the improper adjustment of the air nozzle will make the glass bottle initial mold and mold temperature uncoordinated, and it is easy to create cold spots on the glass bottle body, which directly affects the smoothness.

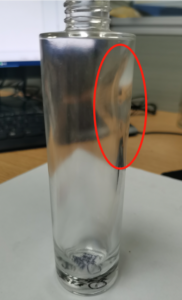

7. The glass feed liquid in the kiln is not clean or the temperature of the material is uneven, which will also cause bubbles, small particles and small hemp billets to appear in the output glass bottle. Glass bottle is a traditional beverage packaging container in my country, and glass is also a very historical packaging material. With many kinds of packaging materials flooding into the market, glass containers still occupy an important position in beverage packaging, which is inseparable from its packaging characteristics that cannot be replaced by other packaging materials.

8. If the machine speed is too fast or too slow, the glass bottle body will be uneven, the thickness of the bottle wall will be different, resulting in mottled.

How can we tell if a glass bottle is good? Here are 2 tips for choosing a glass bottle!

First of all, the glass bottle body should be pure and transparent. If the glass bottle looks impurity and bubbles, it will appear rough and affect the aesthetics of the glass.

Secondly, the bottle mouth should be smooth and neat. On the one hand, it affects the comfort, and more directly affects the sealing of the glass bottle.

Now you have the idea of how to avoid bubbles and scratches in the glass production. In Shengwei glass we will control the above mention causes and conduct a fully inspection before the delivery. You can totally set your mind at rest if corporate with us.

Spot on with this write-up, I absolutely believe that this web site needs much more attention. I’ll

probably be back again to read more, thanks for the information!

Thanks for your attention. Hope you will back to us soon. We will keep share our article on the website.

Very good blog post. I absolutely love this website. Keep writing!