Continuing the last blog–How to Test Glass Bottles, we know that all products should be fully inspected before they leave the factory and this is the key procedure to ensure our stable quality. And in this week, we are going to talk about what kind of glass bottle will be a defective product.

1 Appearance quality requirements

1.1 Foreign objects: No rust, oil, water stains that are difficult to erase, and no paper scraps, insects, hair, broken glass, metal, a lot of dust and other foreign objects in the bottle,

1.2 Bottle mouth: no large or small mouth, bell mouth, crack, breakage, burr; no obvious skew or displacement of the bottle neck, which affects filling and compatibility.

1.3 Big head and fat head: Looking at the position of the screw teeth on the bottle mouth from the side, there is a phenomenon similar to swelling and bulging. This kind of problem is generally not suitable for the cap.

1.4 Thread: It must be smooth and flat, without deformation, incompleteness or roughness.

1.5 Clamping line: There should be no obvious protrusions, dislocation of the double clamping lines and sharp burrs that affect the safety and compatibility, which usually occurs when the mold is old.

1.6 The bottle mouth is uneven:

It usually appears in large-mouthed bottles. The bottle is placed on the glass, and the obvious height can be seen. Usually, it is divided into four directions and plugged with a 0.3 MM feeler gauge can be judged as qualified. If it exceeds the standard, it will affect the sealing.

1.7 Tilt head and head displacement: Visually observe that the head and neck of the product is skewed or the head is shifted to one side, which can be clearly seen when it cooperates with the cover;

1.8 Bumps/Scratches

Visually, it can be seen that the two bottles collide together to produce production scars, and the frosting will be obvious when shipping. The main cause is in the frosting process, and the silk screen spraying and bottle polishing will not occur in general.

2. Insufficient bottle shoulders

2.1 Bottle shoulder shape

The shoulder shape of the bottle is not full enough.

2.2 Thin shoulders

Shoulder material is too thin, 1.5 MM can not reach

2.3 Parting line thick/displacement

Shoulder parting line with scratches or visible steps

3. Bottle defects

3.1 The bottle body is skewed

Crooked body, the bottle is not well formed, and the bottle is skewed. It can be seen by visual inspection that it affects the appearance and filling. The higher the bottom, the smaller the bottle is likely to appear. Normally, it is not more than 1.5 degrees;

3.2 The bottle body is deformed and uneven

It is mainly touched by hand, and it feels uneven to the touch, which affects post-processing and even affects the capacity, so it cannot be used.

3.3 Wrinkled skin, material knot

The bottle body is wrinkled or there is a mark like a parting line appearing on the bottle body, it can be clearly seen that the hand feeling will also be obvious, unacceptable and affecting the appearance

3.4 Bottle body watermark/watermark, material mark

The bottle body has water ripple-like lines or one or more marks, which generally appear horizontally. It can be seen by visual inspection that it is generally unacceptable to feel the hand feeling, which affects the appearance.

3.5 The thickness of the bottle body should be uniform within the receiving country, the thickness should not be less than 1.5 mm, and the thickness deviation should not be more than 30%.

3.6 Uneven feeding of the bottle body

Visual inspection of the bottle, you will feel that the bottle body is uneven, or the line of the inner wall of the bottle body is not smooth, and the inner wall of the bottle body is divided into two sections. Generally, lotion perfume will have it, but cream will not have it. The lotion perfume is the reason for blowing. The higher the bottle, the more obvious it is. Generally, it is invisible after filling with water and milk. If the shoulder material is uneven, there will be any products. It is mainly the mold design and operation, but sometimes it is also related to the shape of the bottle, and the cutting is not good.

4. Huff line defect

4.1 The huff line is thick or misplaced

The huff line can be seen visually, and can be clearly felt by touching the parting line by hand, and the position of the huff line is dislocated or raised/scraped;

4.2 huff line concave

Touch the huff line with your hand, you can obviously feel that the huff line is recessed, and the solid color or electroplating process will be obvious after processing, which will affect the appearance.

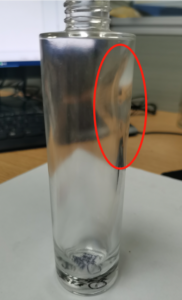

4.3 Double huff line

There are two huff line on one side of the bottle at the same time. The main reason is that the finished mold and the initial mold are not aligned properly. There are two huff line . It can be clearly seen by visual inspection. There are slight but not thick, within 2 MM.

5. Bottle bottom defects:

5.1 The bottom of the bottle has no uneven deformation and affects the stability.

5.2 All parts of the bottle should be free from cracks, breakage.

5.3 The mold usually appears at the thick position of the bottom of the bottle, and one or more dents can be seen

5.4 Thick and thin bottom: For the same product, some bottles have thick material inside the bottom of the bottle, and some are thin

5.5 Sloping bottom: for the same bottle, the internal feeding of the bottom of the bottle is uneven, and the feeding of the bottom of the bottle is high on one side and low on the other.

5.6 Bulkhead line turning: The line at the bottom of the bottle is called bulkhead line, but the line cannot be turned up to the bottle body, only the bottom of the bottle, such as turning up to the bottle body, we call it bulkhead line turning, which affects the bottle body Exterior;

5.7 The bottom is uneven and wobbly:

This problem occurs when the bottle is placed on a table or glass and swings left and right. Usually, the swing cannot exceed 3 seconds.

5.8 Bottom bump

It usually appears in the cream jar. The bigger the bottom, the easier it will appear, which will affect the capacity. There should be no obvious bumps, and the solid color is obvious.

6 Process requirements

6.1 Frosting requirements: The surface thickness is appropriate, the thickness is moderate, the frosting position generally does not rise to the bottom of the thread, not lower than the junction of the bottle neck and the bottle body, and no bright spots are allowed on the front of the bottle body

6.2 Printing quality: The content, font, deviation, color and size of the pattern and text must meet the requirements of the standard sample, and the pattern or font must be neat and clear, without obvious font blur, color difference, shift, burr, inaccurate overprinting, etc.

6.3 The strength of printing, bronzing and spraying is tested with 3M810 tape, and there is no obvious fall off (the font is allowed to fall off slightly but does not affect reading); if necessary, use 100 grid, content smear, alcohol resistance, friction test, and no obvious abnormality is required.

7. Other requirements

7.1 Material Requirements

The material requirements of the glass bottle are consistent with the confirmation sample.

7.2 Specifications and Dimensions

Specifications and dimensions must meet the requirements of the drawings.

7.3 Compatibility requirements

The bottle and the cap (the gasket of the nozzle, the inner plug (the inner bowl) must be smooth, and there should be no over-tightening, too loose, tilted head, or slippery teeth; the distance between the bottle and the cap (the nozzle) should be within 0.3-0.8mm. between.

7.4 Capacity Requirements

When the content is filled to the shoulder position of the container (90% of the full mouth of the aesthetic filling height), it must be greater than the product labeling value and less than the product 105% labeling value.

7.5 Air tightness requirements

Keep it for 15 minutes under the vacuum negative pressure of -0.08 Mpa, and the test has no leakage.

Don’t underestimate a small glass bottle. There are hundreds of quality concerns about its quality. Considering the problem of matching accessories, we will even have more concern on all aspect. if want to know more knowledge about cosmetic glass bottles, keep following us, and any questions or inquiries, just feel free to contact us now.

Very good blog post. I absolutely love this website. Keep writing!

Thanks for your comment. We will sure keep writing on it.:)